Tires are one of the most critical components of any vehicle, as they are the only point of contact between the vehicle and the road. They provide grip, stability, and comfort, making them a crucial factor in ensuring safety while driving.

Tires have come a long way since their inception, with modern technology enabling manufacturers to create tires that are durable, efficient, and eco-friendly. In this article, we will delve into the history, types, components, construction, maintenance, safety, and recycling of tires.

What You will Learn From This post?

- What is tire and its meaning?

- History Of Tires

- Types of Tire

- About Tire Construction

- Understand Tire Size and its Markings codes

- Maintenance of Tire

- Tire Safety Tips

- Tire Recycling and Disposal

1 – What Is Tire?

A tire is a round, rubber object that is mounted onto a wheel rim and inflated with air. Tires are typically used on vehicles such as cars, trucks, buses, motorcycles, and bicycles, as well as on industrial equipment like tractors and forklifts.

The primary purpose of a tire is to provide a cushioning layer between the vehicle and the road surface, protecting the vehicle from damage and providing grip and traction to help the vehicle move smoothly and safely.

Tires come in a wide variety of sizes, shapes, and designs to suit different types of vehicles and applications, and they are made from a range of materials including natural rubber, synthetic rubber, and other additives like carbon black, silica, and various chemicals.

2 – Brief History Of Tires

Tires have been around for centuries, with the first known rubber tire being invented by Robert William Thomson in 1845. However, the modern pneumatic tire was invented by John Boyd Dunlop in 1888, who created it for his son’s tricycle.

It wasn’t until the early 1900s that tires began to be mass-produced and used on automobiles. Since then, tires have evolved significantly, with new materials and construction methods making them safer and more efficient.

- Early tires: In ancient times, people would use strips of leather or other materials to wrap around the wheels of their carts or chariots, providing some cushioning and protection against wear and tear.

- Rubber tires: In the mid-1800s, rubber became a popular material for making tires. Scottish inventor Robert William Thomson is credited with inventing the first rubber pneumatic tire in 1845, although it was not widely adopted at the time.

- Bicycle tires: The first pneumatic bicycle tire was developed by John Boyd Dunlop in 1888, revolutionizing the sport of cycling and paving the way for pneumatic tires to become the norm for all kinds of vehicles.

- Car tires: In 1895, André Michelin developed the first detachable pneumatic car tire, which made it easier and faster to repair flat tires. This innovation helped to make cars a more practical and convenient mode of transportation.

- Radial tires: In the 1940s, French engineer Michelin introduced the radial tire, which had a different internal structure that provided better handling and fuel efficiency than previous tire designs. Radial tires quickly became popular for cars and other vehicles.

- Run-flat tires: In the early 2000s, run-flat tires were introduced, which can continue to function even if they lose air pressure. This technology is now commonly used in high-end cars and other vehicles.

- Eco-friendly tires: In recent years, tire manufacturers have been developing tires that are more environmentally friendly, using materials like natural rubber and reducing rolling resistance to improve fuel efficiency and reduce emissions.

- Readed tires: In the early 1900s, tire manufacturers began experimenting with adding treads to the surface of tires to improve traction and handling on different types of terrain.

- Snow tires: In the 1930s, the first winter tires were introduced, which had deeper treads and softer rubber to provide better grip on snow and ice.

- Tubeless tires: In the 1950s, tubeless tires were developed, which eliminated the need for an inner tube and improved safety by reducing the risk of blowouts.

- All-season tires: In the 1970s, all-season tires were introduced, which were designed to perform well in a wide range of weather conditions.

- Low-profile tires: In the 1980s, low-profile tires became popular for sports cars and other performance vehicles, as they provided better handling and a sportier look.

- Self-inflating tires: In recent years, tire manufacturers have been working on developing self-inflating tires, which use sensors and inflators to maintain optimal air pressure without the need for manual adjustments.

3 – Tire Types

There are many different types of tires, each designed to perform optimally under specific conditions. Here are some of the most common tire types:

- All-season tires: Designed to provide good performance in all weather conditions, including rain and light snow.

- Summer tires: Designed for warm weather and provide excellent handling and grip on dry roads.

- Winter tires: Designed for cold weather and provide superior traction on snow and ice.

- Performance tires: Designed for sports cars and high-performance vehicles, with a focus on handling and grip.

- Off-road tires: Designed for use on rough terrain, with deeper tread and stronger construction to withstand rough conditions.

- Run-flat tires: Designed to allow a vehicle to continue driving even after a puncture, typically for a limited distance.

- Eco-friendly tires: Designed to reduce rolling resistance, resulting in improved fuel efficiency and lower CO2 emissions.

- Low-profile tires: Designed with a shorter sidewall and wider tread, providing improved handling and a sportier look.

- Trailer tires: Designed specifically for use on trailers, with a focus on durability and weight capacity.

- All-terrain tires: Designed to provide good performance on both on-road and off-road terrain.

4 – Tire Components

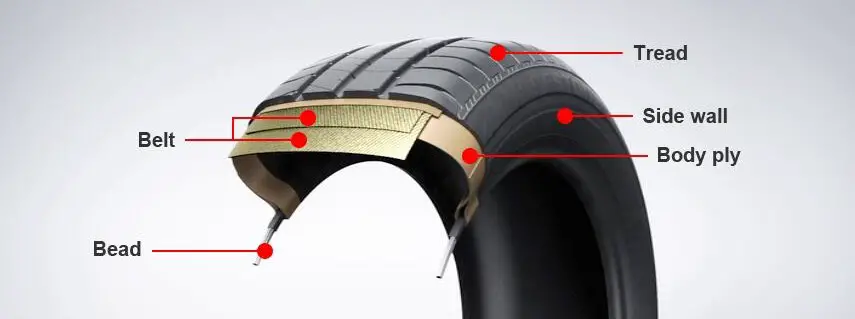

Tires are made up of several components, each with a specific function. Here are the primary tire components:

- Tread: The outermost layer of the tire that comes into contact with the road surface. The tread pattern can vary depending on the type of tire and its intended use.

- Sidewall: The vertical section of the tire that connects the tread to the bead. The sidewall often includes information such as the tire size, brand, and maximum load capacity.

- Bead: The inner edge of the tire that sits on the wheel rim. The bead is usually reinforced with steel wire to provide strength and stability.

- Casing: The body of the tire, which includes the layers of rubber, fabric, and steel cords that make up the internal structure. The casing provides the tire with its shape and strength.

- Belt: A layer of rubber-coated steel cords that sits between the tread and the casing. The belt provides extra reinforcement to the tire and helps to improve stability and handling.

- Inner liner: A layer of rubber that sits between the casing and the inner tube (in tube-type tires) or the air chamber (in tubeless tires). The inner liner helps to retain air pressure and prevent air leakage.

- Shoulder: The area where the tread meets the sidewall. The shoulder can affect the tire’s handling and cornering performance.

- Sipes: Small grooves in the tread blocks that help to improve traction on wet or slippery roads.

- Grooves: The larger channels in the tread pattern that help to displace water and improve traction on wet roads.

- Apex: A layer of rubber or other material that sits between the bead and the casing, providing extra stiffness to the sidewall.

- Rim strip: A strip of rubber or other material that sits between the rim and the tire, protecting the tube from damage and preventing air leakage.

- Valve stem: The small metal or rubber component that allows air to be pumped into the tire. The valve stem is typically located on the inner side of the wheel rim.

- Cap ply: A layer of fabric or steel cords that sits between the tread and the casing, providing extra reinforcement and protection against impact damage.

- Tie bars: Small bridges of rubber or other material that connect the tread blocks, helping to improve stability and reduce tread wear.

- Treadwear indicators: Small raised bars or other features built into the tread that indicate when the tire is worn down and needs to be replaced.

- Traction-enhancing materials: Some tires include materials like silica or carbon black in the tread compound to improve traction and handling.

- Run-flat technology: Some tires are designed to allow a vehicle to continue driving for a limited distance at a reduced speed even after a puncture or other damage that would normally cause a flat tire.

- Bead filler: A material that sits between the bead and the rim, helping to create an airtight seal and prevent air leakage.

5 – Tire Construction

Tires can be constructed in various ways, each with its unique benefits and drawbacks. Here are the primary tire construction methods:

- Bias-ply construction: A traditional construction method where the plies are laid diagonally across the tire, providing a sturdy construction.

- Radial-ply construction: A modern construction method where the plies are laid perpendicular to the tire’s direction of travel, resulting in a more flexible and comfortable ride.

- Belted-bias construction: A combination of the bias-ply and radial-ply construction methods, providing a balance of strength and comfort.

- Tubeless construction: A construction method where the tire does not require an inner tube, resulting in improved durability and resistance to punctures.

- Run-flat construction: A construction method that allows a tire to continue functioning even after a puncture, typically for a limited distance.

- Self-sealing construction: A construction method that includes a sealant inside the tire, allowing it to seal punctures on its own.

- Airless construction: A construction method that eliminates the need for air, resulting in a tire that cannot be punctured or go flat.

- Dual construction: A construction method that combines two different types of tires, typically a summer tire and a winter tire, to provide optimal performance in all weather conditions.

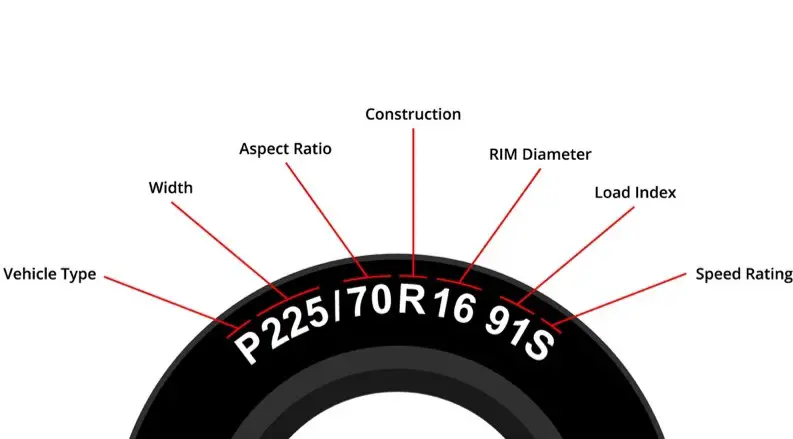

6 – Tire Size and Markings

Tire size and markings provide valuable information about a tire’s specifications and capabilities. Here are some of the most common tire size and marking indicators:

- Tire width: The width of the tire measured in millimeters.

- Aspect ratio: The height of the sidewall as a percentage of the tire’s width.

- Rim diameter: The diameter of the wheel the tire is designed to fit.

- Load index: A number that indicates the tire’s weight capacity.

- Speed rating: A letter that indicates the tire’s maximum safe speed.

- Treadwear rating: A number that indicates the tire’s expected lifespan.

- Traction rating: A letter that indicates the tire’s ability to stop on wet roads.

- Temperature rating: A letter that indicates the tire’s ability to withstand heat.

- DOT code: A code that indicates the tire’s manufacturer, plant location, and production date.

- UTQG rating: A rating system that indicates a tire’s treadwear, traction, and temperature capabilities.

- M+S or M/S: Indicates a tire’s suitability for use in mud and snow.

- All-season, winter, or summer: Indicates the tire’s suitability for use in different weather conditions.

- Directional or non-directional: Indicates the tire’s direction of rotation.

- Load range and ply rating: Indicates the tire’s load-carrying capacity.

- Reinforced or OEM: Indicates the tire’s strength and suitability for use on a specific vehicle.

7 – Tire Maintenance

Proper tire maintenance is essential to ensure optimal performance, safety, and lifespan. Here are some essential tire maintenance tips:

- Proper tire inflation: Maintain the recommended tire pressure to ensure optimal performance, fuel efficiency, and safety.

- Regular tire rotation: Rotate the tires regularly to ensure even wear and prolong their lifespan.

- Tire balancing: Balance the tires to ensure a smooth ride and prevent premature wear.

- Wheel alignment: Align the wheels to ensure optimal handling, stability, and tire lifespan.

- Tire repair: Repair punctures promptly to prevent further damage and ensure safety.

- Check tire pressure: Check the tire pressure regularly, at least once a month, and before long trips.

- Inspect tire tread: Check the tire tread regularly for signs of wear or damage.

- Align tires: Ensure that the tires are properly aligned to prevent uneven wear and improve handling.

- Check for damage: Inspect the tires for signs of damage, such as cuts, bulges, or cracks.

- Clean tires: Clean the tires regularly to remove dirt, grime, and debris.

- Avoid overloading: Do not exceed the tire’s load capacity to prevent damage and ensure safety.

- Avoid harsh driving: Avoid harsh driving, such as hard braking or accelerating, to prevent premature wear and reduce the risk of accidents.

- Store tires properly: Store the tires in a cool, dry, and dark place, away from direct sunlight or heat sources, and stack them horizontally.

8 – Tire Safety

Tire safety is crucial to ensure optimal performance, handling, and safety. Here are some essential tire safety tips:

- Tire blowouts: Check the tire pressure regularly and inspect the tires for signs of wear or damage to prevent blowouts, which can lead to accidents.

- Hydroplaning: Reduce speed in wet conditions and ensure that the tires have adequate tread depth and traction to prevent hydroplaning, which can cause loss of control.

- Tire punctures: Inspect the tires regularly and repair punctures promptly to prevent further damage and ensure safety.

- Overloading: Do not exceed the tire’s load capacity to prevent damage and ensure safety.

- Proper tire selection: Select the appropriate type of tire for the vehicle and the intended use, such as all-season, winter, or summer tires, to ensure optimal performance and safety.

9 – Tire Recycling and Disposal

Tire recycling and disposal are essential to prevent environmental pollution and reduce waste. Here are some essential tire recycling and disposal facts:

- Environmental impact of tires: Tires are made of synthetic rubber, which is non-biodegradable and can take hundreds of years to decompose. Improper tire disposal can lead to environmental pollution and health hazards.

- Recycling options: Tires can be recycled into various products, such as playground surfaces, flooring, and fuel. Recycling programs vary by location and may require a fee or a special collection.

- Tire disposal regulations: Tire disposal regulations vary by location and may require proper storage, transportation, and disposal methods. Improper tire disposal can lead to fines and legal consequences.

Conclusion

Tires are essential components of modern transportation, providing mobility, safety, and comfort. Understanding tire types, components, construction, size, markings, maintenance, safety, and recycling can help drivers select, use, and dispose of tires properly. Future developments in tire technology, such as eco-friendly materials, smart sensors, and self-healing features, promise to improve tire performance, durability, and sustainability.

References

AR Jeet has been a tire mechanic for over 2years. He has worked on all types of vehicles, from cars and trucks to RVs and ATVs and motorcycles. He has seen it all when it comes to tires, and he knows how to fix them.

AR Jeet is a tire expert, and he is passionate about his work. He loves to help people keep their vehicles running smoothly, and he is always happy to answer any questions that people have about their tires.

If you need help with your tires, or if you just want to learn more about them, then AR Jeet is the man to talk to. He will be happy to help you out, and he will make sure that you get the best possible solution.

He has a blog [Tirespick.com] where he writes about all things tire-related, and he is always happy to help people with their tire needs. Know more about AR Jeet.